We may earn money or products from the companies mentioned in this post.

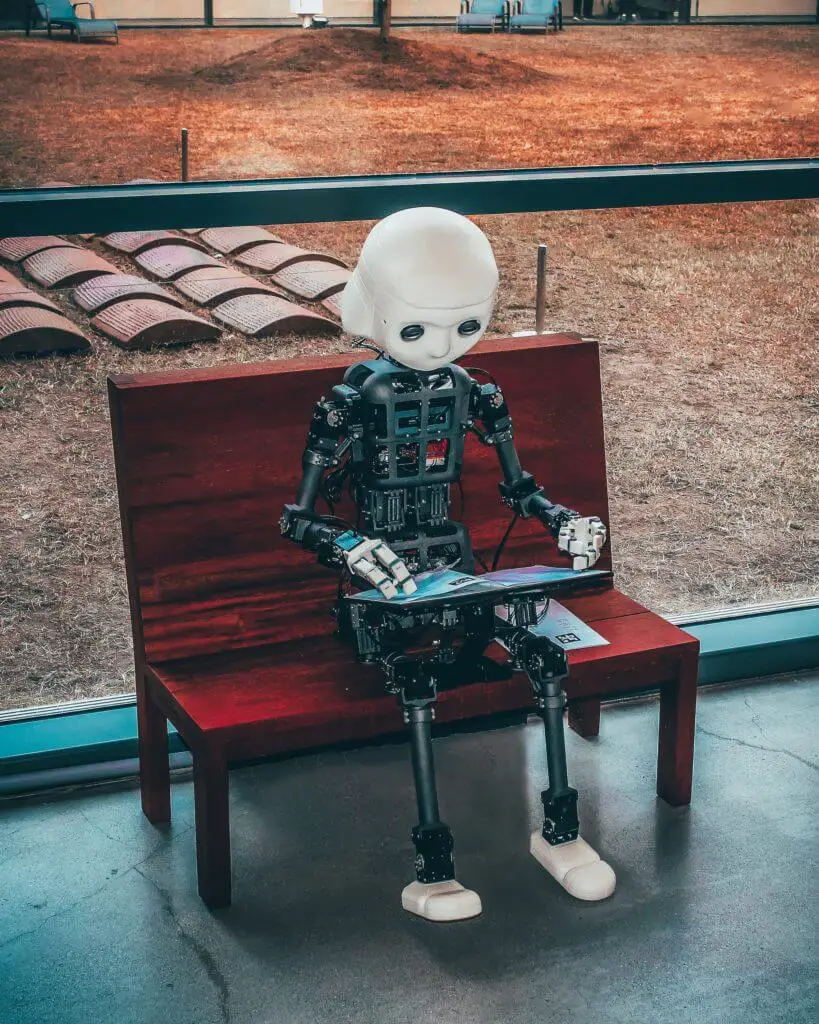

The Growing Robotic Workforce

The rapid intervention of robots into the labor force has reshaped the structures of workplaces. Robots can improve efficiency and quality, lower costs, and even help human counterparts create more jobs. However, more robots may reduce the need for managers. According to a study carried out on the effect of automation on businesses, as businesses become more automated, certain types of managers become obsolete.

Human error is drastically reduced as various tasks and processes are automated. Managers must also closely monitor their employees’ work. “Technology can generate reports on what the robots did, what material they used, and they can aggregate it at the firm level, division level, to easily get lots of different operational metrics,” Wu explained. “And those are the sorts of things that managers are prone to doing.”

Catering For the Shortage or Rendering Workers Jobless?

The changing composition of employment accounts for the decrease in managerial positions. Although robot adoption leads to increased jobs, Wu claims that the increase is not uniform across skills. Low-skilled workers, such as box packers, and high-skilled workers, such as engineers, are on the rise, while middle-skilled workers are in jeopardy.

“When you see a significant decrease in middle-skilled work and an increase in the extremes — high- and low-skilled labor — it means that the type of managers required to manage this new workforce will be different. “Because of standardization and efficiency, someone who supervises low-skilled workers can manage a lot more people when the company brings in robots. However, the transition is more ambiguous for managers of highly skilled workers.

These employees are typically in charge of innovation rather than operations, which is more difficult to quantify. Highly skilled professionals excel at their jobs, often outperforming their managers. “They don’t need managers to tell them how to do their jobs or make sure they arrive on time,” Wu explained. “Managing highly skilled workers is more akin to coaching or advising.” Managers advise them to assist them in doing their best at work, which is very different from supervising work.”

Industrial robots are self-contained, reprogrammable machines that perform welding, painting, and packaging tasks. They are entirely self-contained and do not require human intervention to operate. Between 1993 and 2007, the number of industrial robots in the United States quadrupled, reaching one per thousand workers, according to Acemoglu and Restrepo. Europe is slightly ahead of the United States regarding industrial robot adoption, with 1.6 robots per thousand workers installed during that period.

The displacement effect, in which robots or other automation perform tasks previously performed by workers, harms wages and employment. Technology can also increase productivity by making lessons easier to complete or creating new jobs and tasks for workers. According to the researchers, automation technologies always have displacement and productivity effects, but robots have a more substantial displacement effect.

They discovered that the increase in robots (about one per thousand workers) between 1990 and 2007 reduced the average employment-to-population ratio in a zone by 0.39 percentage points and average wages by 0.77 per cent compared to commuting zones with no exposure to robots. Adding one robot to an area reduces employment by approximately six workers. However, what happens in one geographic area impacts the economy, and robots in one place can have a positive spillover effect.

These benefits to the rest of the economy include lower commodity prices and increased shared capital income. Including this spillover, one robot per thousand workers has a slightly lower impact on the population, resulting in a 0.2 percentage point reduction in the employment-to-population ratio and a 0.42 per cent reduction in wages. Thus, adding one robot reduces employment by 3.3 workers nationwide. Acemoglu and his co-authors discovered that French manufacturing firms that added robots became more productive and profitable, but that increases in robot use led to an industry-wide decline in employment.

Impacts of The Shift

The impact of robots varies by industry, geographic area, and population group. Unsurprisingly, the result of robots is concentrated in the manufacturing industry. According to the researchers, the automotive industry has adopted robots more than any other industry, employing 38 per cent of existing robots and adopting up to 7.5 robots per thousand workers. Robots are used by 15% of the electronics industry and 10% of the plastics and chemicals industries.

Employees in these industries experienced the most damaging consequences, and researchers anticipate negative implications for construction, retail, and personal services workers. While the automotive industry adopted robots more quickly and to a greater extent than other sectors, it did not drive the study’s findings. When that industry was removed from the equation, the researchers found that the impact of robots remained consistent.

Robots are most likely to affect low- and middle-income workers, mainly blue-collar workers such as machinists, assemblers, material handlers, and welders. Acemoglu and Restrepo are authors. Robot adoption affects both men and women, with men slightly more affected. Manufacturing jobs have the most significant impact on men. Non-manufacturing jobs had the greatest impact on women.

Robots have a negative impact on workers of all educational levels, though those without a college degree have been impacted far more than those with a college degree or higher. The researchers also discovered that robot adoption has no positive effect on workers with master’s or advanced degrees, implying that, unlike other technologies, industrial robots do not directly complement high-skill workers.

Conclusion

Robotic technology is expected to advance further, with one optimistic scenario predicting that the number of robots in the world will quadruple by 2025. According to the researchers, this would imply 5.25 more robots per thousand workers in the United States, a one percentage point lower employment-to-population ratio, and a 2% lower wage growth between 2015 and 2025. In a more conservative scenario, the number of robots could increase slightly more petite than threefold, resulting in a 0.6 percentage point decrease in the employment-to-population ratio and 1% lower wage growth.

According to Acemoglu, the economic crisis caused by the COVID-19 pandemic will exacerbate both the positive and negative effects of robots and technology. “The good news is that we are extremely reliant on digital technologies.” We wouldn’t be able to use Zoom or other advanced digital technologies for teaching and teleconferencing if we didn’t have these advanced digital technologies.

We wouldn’t be able to keep factories running in many areas because workers haven’t returned to work fully,” he said. “However, this increases the demand for automation by the same token.” If the automation process goes too far or had some negative effects, as we discovered, those will be multiplied as well. As a result, we must take those into consideration.”

You Might Like–https://www.thefullbyte.com/2022/06/12/the-freelancing-economy/